|

| Group A R32 GT-R with OEM MAF |

The stock RB26dett has a pretty unique arrangement for measuring the amount of air that comes into the engine. It has a dual MAF, or mass airflow meter. Most production cars have a single MAF, but for the RB26 Nissan decided to double up. The way they work, there is a heated element in a tube. Air passes over that heated element, and from the change in resistance, the amount of voltage varies. Since they can put out anywhere from 0-5 volts, it is not often that you will see a "CODE" or Check Engine Light if it is faulty.

Watch out for cheap knock off MAF. There are many out there on the internet. You are better fixing your OEM sensor, or buying a used OEM than a new aftermarket MAF. If you car has what seems like a 2500 rpm limiter, it might have a MAF going bad.

Code 11 - crank angle sensor signal system

Code 11 - crank angle sensor signal system

Code 12 - Air flow meter signal system

Code 13 - Engine temperature signal system

Code 21 - Ignition signal system

Code 34 - Detonation sensor signal system

Code 41 - Intake temperature sensor signal system

Code 43- Throttle sensor signal system

Code 51 - No error

MAF - OEM part number: 22680-05U00 .The stock RB26 65mm body(2.55 inches), 70 mm hose connection. MAF(Mass Air Flow) sensors are good for about 400 wheel horsepower. Above then they run out of range and max out their voltage. A popular replacement(in 2000) is the Nissan 300ZX meters. A 300ZX uses one 75 mm body MAF - we double up for the GT-R..They are physically larger(80mm hose connection). More recently the R35 blade style MAF have become popular. With most stand alone engine management, cars generally go to a MAP(Manifold absolute pressure) sensor. The thing about MAP based tuning is that the density of air is dependent on temperature and pressure. Some ECU's swap over to MAP based load, but with the ITB's, it can be a difficult thing to tune for part throttle.

Code 11 - crank angle sensor signal system

Code 11 - crank angle sensor signal systemCode 12 - Air flow meter signal system

Code 13 - Engine temperature signal system

Code 21 - Ignition signal system

Code 34 - Detonation sensor signal system

Code 41 - Intake temperature sensor signal system

Code 43- Throttle sensor signal system

Code 51 - No error

MAF - OEM part number: 22680-05U00 .The stock RB26 65mm body(2.55 inches), 70 mm hose connection. MAF(Mass Air Flow) sensors are good for about 400 wheel horsepower. Above then they run out of range and max out their voltage. A popular replacement(in 2000) is the Nissan 300ZX meters. A 300ZX uses one 75 mm body MAF - we double up for the GT-R..They are physically larger(80mm hose connection). More recently the R35 blade style MAF have become popular. With most stand alone engine management, cars generally go to a MAP(Manifold absolute pressure) sensor. The thing about MAP based tuning is that the density of air is dependent on temperature and pressure. Some ECU's swap over to MAP based load, but with the ITB's, it can be a difficult thing to tune for part throttle.

|

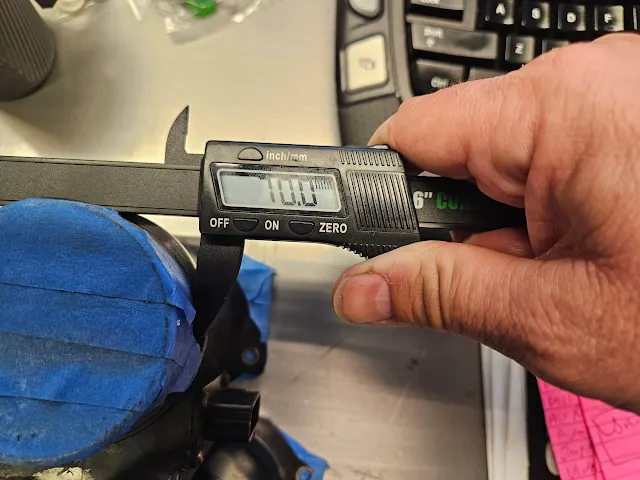

| OEM RB26 MAF at the body. The inlet is about 63mm ID. |

|

| OEM RB26 MAF at the hose connector side. 70 mm Based on this then Z32 are 75 mm, not 80 mm as I have always used. |

|

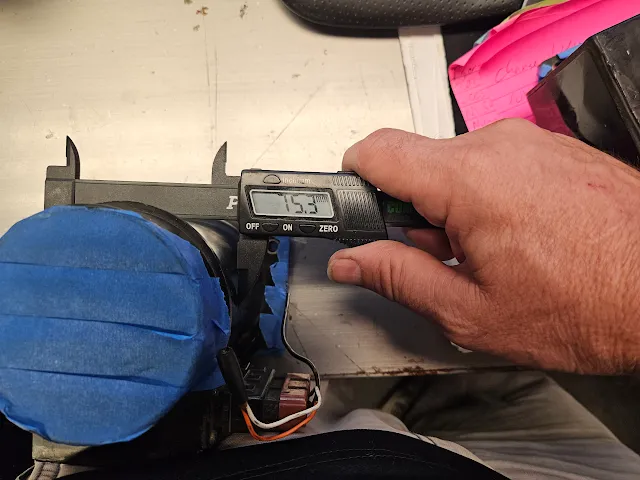

| Z32 MAF at the body. 75.3 mm on the body, and 80 mm at the hose side. |

|

| Z32 MAF at the body. 75.3 mm on the body, and 80 mm at the hose side. |

The thing is, the mass air flow meter are probably 25 years old, or older now. Since they are one of the main inputs into the ECU to schedule fuel and timing, what they have to say is very important. Often we see the solder joints inside the MAF go bad. In this case, it is possible to open up the top, resolder, and you are back on the road. Check out these links below.

65 mm = 2.55 inches

70 mm = 2.75 inches

80 mm = 3.15 inches

90 mm = 3.5 inches

How to repair RB26 MAF - Skylines Australia

https://youtu.be/0nnigpKWFnY

R35/Nissan 70 ----- 300---------600

R35/Nissan 76.5-----350 --------700

Strengths of Mass Air Flow

Weaknesses of Mass Air Flow

It may seem like there are a lot of weaknesses of MAF systems, but it is truly hard to emphasize just how amazing and important the strengths are. It is no secret that the majority of OEMs today are implementing MAF systems as the primary control strategy. There is a good reason for this, namely that engines can be controlled much more precisely (with the goal of meeting stricter and stricter emissions standards) with a MAF system than any other type of control strategy.

300ZX - Z32 MAF, 80 mm hose connection (3.15 inches). You need a new connector, you need tuning. Not plug and play unless you have a Power FC, or NISTUNE. They will do about 400 hp each, so will meter about 800 hp of air in a twin setup for an RB26 twin turbo car.

R35 - There are drop in adaptors available. Even in black so they look near stock.

NISTUNE MAF adaptors

OEM Nissan sensor

Part number 22680-7S000. This is used on most current Nissan engines. Commonly referred to as the R35 GTR sensor but they’re actually used on everything from the GTR to the VK56 powered trucks and down to the lowly Tiida 4 cylinder. Nissan simply adjust the housing diameter to give them the required airflow range for the different engine sizes. Larger engines often use twin sensors. They’re good for around the same horsepower range as the Z32 MAF in a similar diameter housing but this can be adjusted by using different diameter housings.

PMAS “HPX” sensor

These are a custom sensor developed by Precision Mass Airflow Sensors in USA. More expensive than the Nissan sensor but good for big horsepower. New connectors are available for these and they come with a generous length of wire attached. More details below.

65 mm = 2.55 inches

70 mm = 2.75 inches

80 mm = 3.15 inches

90 mm = 3.5 inches

How to repair RB26 MAF - Skylines Australia

https://youtu.be/0nnigpKWFnY

OEM MAF metering ranges

From Skylines Australia and Sydneykid (converted to RWWP)

------ --------- OD mm--- RWHP ---- RWHP ---- BHP ------ BHP

No of AFM's ---- -------- 1 ---------- 2 ------------- 1 -------- 2

RB26 ---------- 65 ------- 200 ------ 400 ------- 271 ------ 474

RB20/25 ------ 80 ------- 300 ------ 600 ------- 376 ------ 683

Z32 ------------- 8075---- 340 ----- 685 ------- 415 ------ 763

Q45 ------------ 90 ------- 400 ------ 810 ------- 479 ------ 890

R35/Nissan 76.5-----350 --------700

R35/Nissan 88.9-----500--------1000

PMAS HPX 63.5----580 ----- 1160

PMAS HPX 70 -----640------- 1280

PMAS HPX 76.5 ---830 ----- 1660

PMAS HPX 88.9 ---1130 ------2260

This is a decent rule of thumb for MAF flow to horsepower. Like any rule of thumb its not exact, and misses a few factors, but its close enough to eyeball.

N/A and Turbo Engine HP= MAF (g/s) * 1.25

Supercharged Engine HP=MAF (g/s) *1.1

N/A and Turbo Dynojet WHP manual= MAF (g/s) * 1.1

Supercharged Dynojet WHP manual =MAF (g/s) *0.95

As you can see in this HKS chart, a stock MAF at around 5 volts, or maxed out is about 275 g/s, that equates to just about 340 hp at the engine each. I find the OEM sensors are about done by 4.7 to 4.8 volts or 200 g/s which is about 250 at the engine, or 220 at the wheels each.

Strengths of Mass Air Flow

- Extremely accurate fueling and spark delivery across a diverse range of engine conditions (at least while in steady-states): the holy grail for engine management. A properly set-up MAF system can adapt to changes in weather and altitude with ease.

- Minor changes to engine equipment (i.e. headers, minor camshaft changes, intakes that do not significantly alter the placement of the MAF) do not require recalibration of the ECM.

Weaknesses of Mass Air Flow

- MAF systems are extremely intolerant of vacuum leaks. Any leaks between MAF sensor and engine generally cause all manner of odd problems, running lean in most cases due to un-metered air making it into the engine.

- MAF sensors can be extremely sensitive to how they are “clocked” – merely rotating the sensor at a given spot in the intake tract can be sufficient to significantly change its output.

- MAF sensors require laminar flow to read 100% accurately. True laminar fluids do not exist so this introduces some degree of inaccuracy to MAF sensor readings. Placing MAF sensors near bends, size transitions or obstructions where flow is less laminar greatly magnifies this issue.

- A MAF sensor can be a flow restriction in cases where the MAF housing is the smallest portion of the intake system.

- Hot-wire MAF elements are very fragile. Debris can destroy delicate wires easily. Dirt and oil deposits can build up on the sensor element, adversely affecting readings.

- MAF systems have a relatively poor response to transient conditions, such as sudden throttle changes. This is explained by the time it takes air to move from the MAF sensor where it is measured to the cylinder where it can be involved in combustion.

- MAF sensors are not “one-way” sensors – reversion from a camshaft with large amounts of overlap can cause air to be metered on its way in to the engine and then again on its way out resulting in an artificially high MAF reading. This can almost always be fixed by placing the MAF sensor sufficiently far from the throttle body, however doing so comes at the expense of making transient response even worse.

It may seem like there are a lot of weaknesses of MAF systems, but it is truly hard to emphasize just how amazing and important the strengths are. It is no secret that the majority of OEMs today are implementing MAF systems as the primary control strategy. There is a good reason for this, namely that engines can be controlled much more precisely (with the goal of meeting stricter and stricter emissions standards) with a MAF system than any other type of control strategy.

Upgrades or Aftermarket

|

| OEM RB26 MAF, CAS, and Consult cable. Part of a Roadtrip Tool spares kit |

OEM - Don't use non Nissan parts

300ZX - Z32 MAF, 80 mm hose connection (3.15 inches). You need a new connector, you need tuning. Not plug and play unless you have a Power FC, or NISTUNE. They will do about 400 hp each, so will meter about 800 hp of air in a twin setup for an RB26 twin turbo car.

|

| R35 to RB26 MAF adaptor from RHDJapan.com |

R35 - There are drop in adaptors available. Even in black so they look near stock.

NISTUNE MAF adaptors

OEM Nissan sensor

Part number 22680-7S000. This is used on most current Nissan engines. Commonly referred to as the R35 GTR sensor but they’re actually used on everything from the GTR to the VK56 powered trucks and down to the lowly Tiida 4 cylinder. Nissan simply adjust the housing diameter to give them the required airflow range for the different engine sizes. Larger engines often use twin sensors. They’re good for around the same horsepower range as the Z32 MAF in a similar diameter housing but this can be adjusted by using different diameter housings.

- 2.75" housing (70 mm) 300 WHP each

- 3″ housing (76.2 mm) 350 WHP each

- 3.5″ housing (88.9 mm) 500 WHP each

PMAS “HPX” sensor

These are a custom sensor developed by Precision Mass Airflow Sensors in USA. More expensive than the Nissan sensor but good for big horsepower. New connectors are available for these and they come with a generous length of wire attached. More details below.

Much more information at NISTUNE forum.

3D printed MAF housings

Look, I am as shocked as you. Someone used 3d printing, for something other than a knockoff of a cupholder! I know, I wasn't sure it was possible. John Kennedy made these ones which fit the Nissan (R35) MAF in a stock size. 70mm OD, 61 mm ID on these.

|

| 3d printed MAF housings for Nissan (R35) MAF |

|

| 3d printed MAF housings for Nissan (R35) MAF |

No comments:

Post a Comment